Design

Making plastic products start with the design. We can help customers design their products to maximze the aesthetic looks, funtionality, and the manufacturing efficiency. PMC have veteran engineers to assist customers with any help they need in making their products.

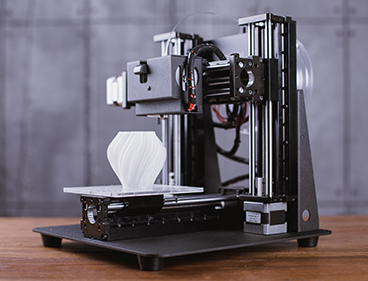

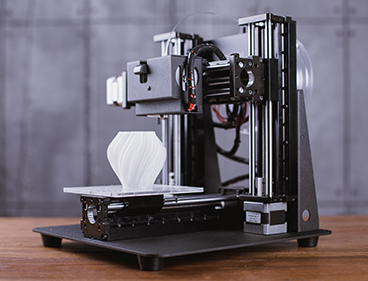

Prototype

Prototyping is key to making quality products. PMC have a small 3D printing machine for small parts and partners we work with for bigger parts to provide customers with prototypes before going into full production.

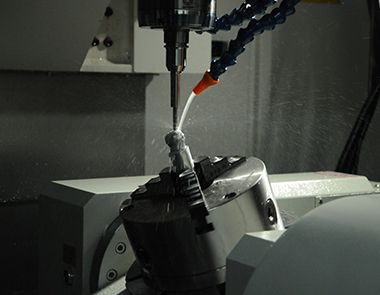

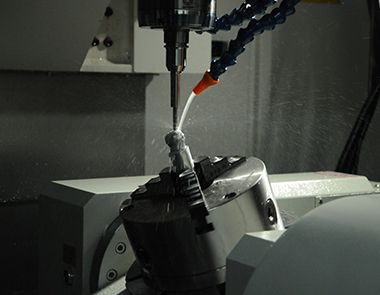

Mold Making

Great quality molds is the key to success for plastic injection parts. Having inhouse mold production guarantee that our molds will be precise and accurate to the specification. We have 7 CNC machines including one 5-Axis CNC machine for the most complicated parts.

Injection Molding

Having great quality molds does not mean good quality products unless you have an experienced working team. Our highly experienced technician have been on the job for over 20 years! We have 23 plastic injection machines' size range from 95 Tonn to 450 Tonn to meet the various need of our customers. We guarantee that we only deliver the products that meet your requirements!

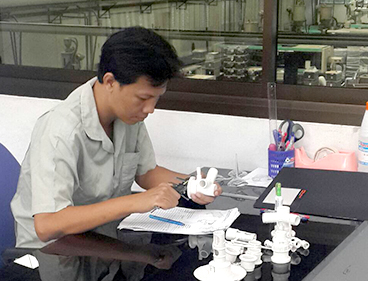

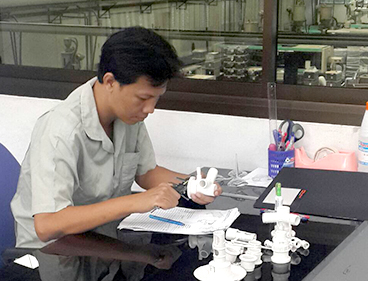

Q.A./Q.C.

Quality Assurance is the heart of our business. While there are countless things that can go wrong in a day, we make it our priority that shipping products to our customers never go wrong. Our QC adjust their sampling and testing standard according to the need of each individial product to ensure that every product only get send to our customers if it meet the standards.

DELIVERY

At PMC, we understands how important is delivery commitment and deadlines. That is why we always communicate with our customers about the project timeline and delivery time. We will always do everything we can to make sure that we meet your delivery needs.

CUSTOMER